Polyvinylchloride

Determining K-value according to Fikentscher

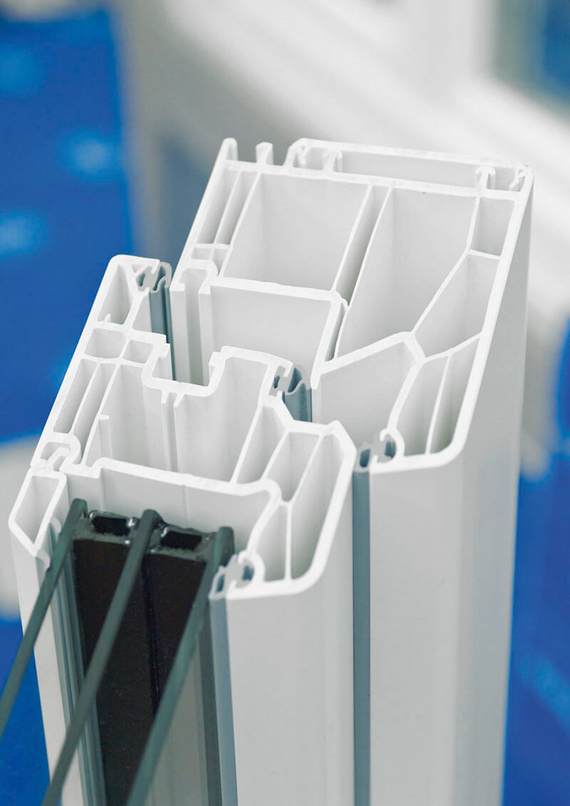

Monitoring the chain length of the basic polymers is essential in order to further improve the quality of PVC as a basic material for window housing, pipes, floor-coverings, containers, and foil as well as for a number of components in the electrics industry. The K-value according to Fikentscher based on the solution viscosity has become accepted as a measure for this. Here, the relatively harmless cyclohexanone serves as a solvent. From production of the rough polymer, to compounding and semi-finished products manufacture by injection-molding technology or extrusion, LAUDA offers PC-controlled K-value measurement, tailored to the current sample rates, from the affordable iVisc measuring system to the fully automated PVS measuring system with sampler.

One version for average sample rates with a good price-performance ratio and great ease-of-use is the two-station measuring system PVS 1/2 with cleaning module based on a Viscotemp 15 viscothermostat. This can easily measure up to four samples per hour. Using a syringe or funnel, the dissolved sample simply needs to be directly inserted into the Ubbelohde which stays in the thermostat. Measuring can then be started. Further process steps (viscometer cleaning and drying) are executed automatically. If desired, sample preparation can also be made automated.

Recommended standards

- DIN EN 1628-2

Plastics – Determination of the viscosity of polymers in dilute solution using capillary viscometers – Part 2: Poly(vinyl chloride) resins

- DIN EN 922

Piping and fittings of unplasticized polyvinylchloride (PVC-U) – Preparation of the samples for determining the viscosity number and calculating the K-value

Typical configuration

Measuring system PVS 1/2 with two measuring stands and automatic cleaning in the Viscotemp 15 viscothermostat

- PVS 1/2 control unit

- Two measuring stands S 5

- A VRM 4 cleaning module for viscometer cleaning

- Viscotemp 15 viscothermostat with through-flow cooler at 25 °C

- Ubbelohde viscometer of size Ic with connections for emptying and rinsing

- Sample preparation system including balance and dosing unit

- Heated magnetic stirring block for dissolving PVC at 80 °C

Applications Polymers

Viscosity number of polyamides (PA) and polybutylene terephthalates (PBT)

Molar mass and IV value of hyaluronic acid products and absorbable polymers

Degree of polymerization of insulation paper using solution viscosity